Welcome to Dongguan Yinso Medical Packaging Co.,Ltd.

Welcome to Dongguan Yinso Medical Packaging Co.,Ltd.

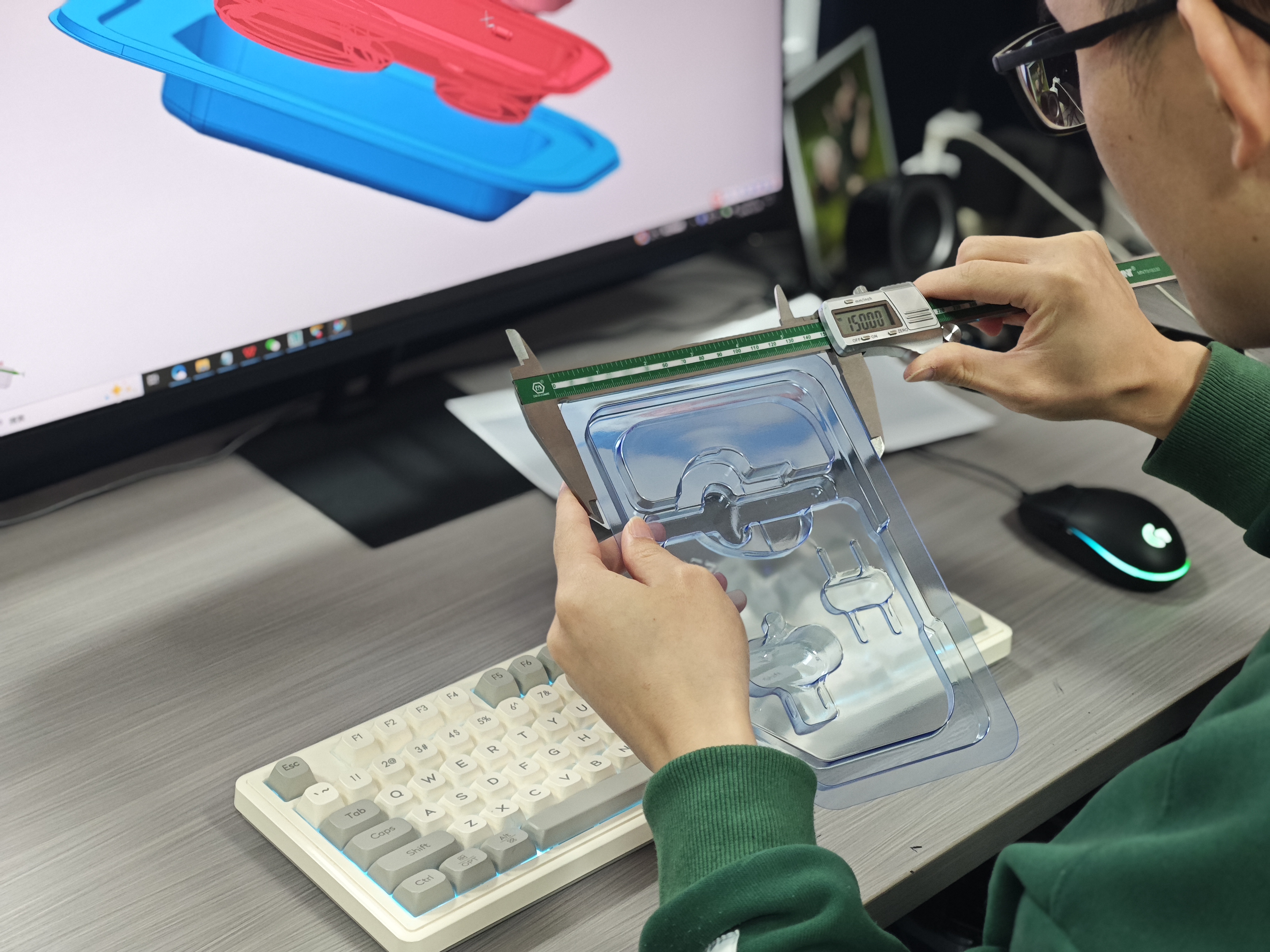

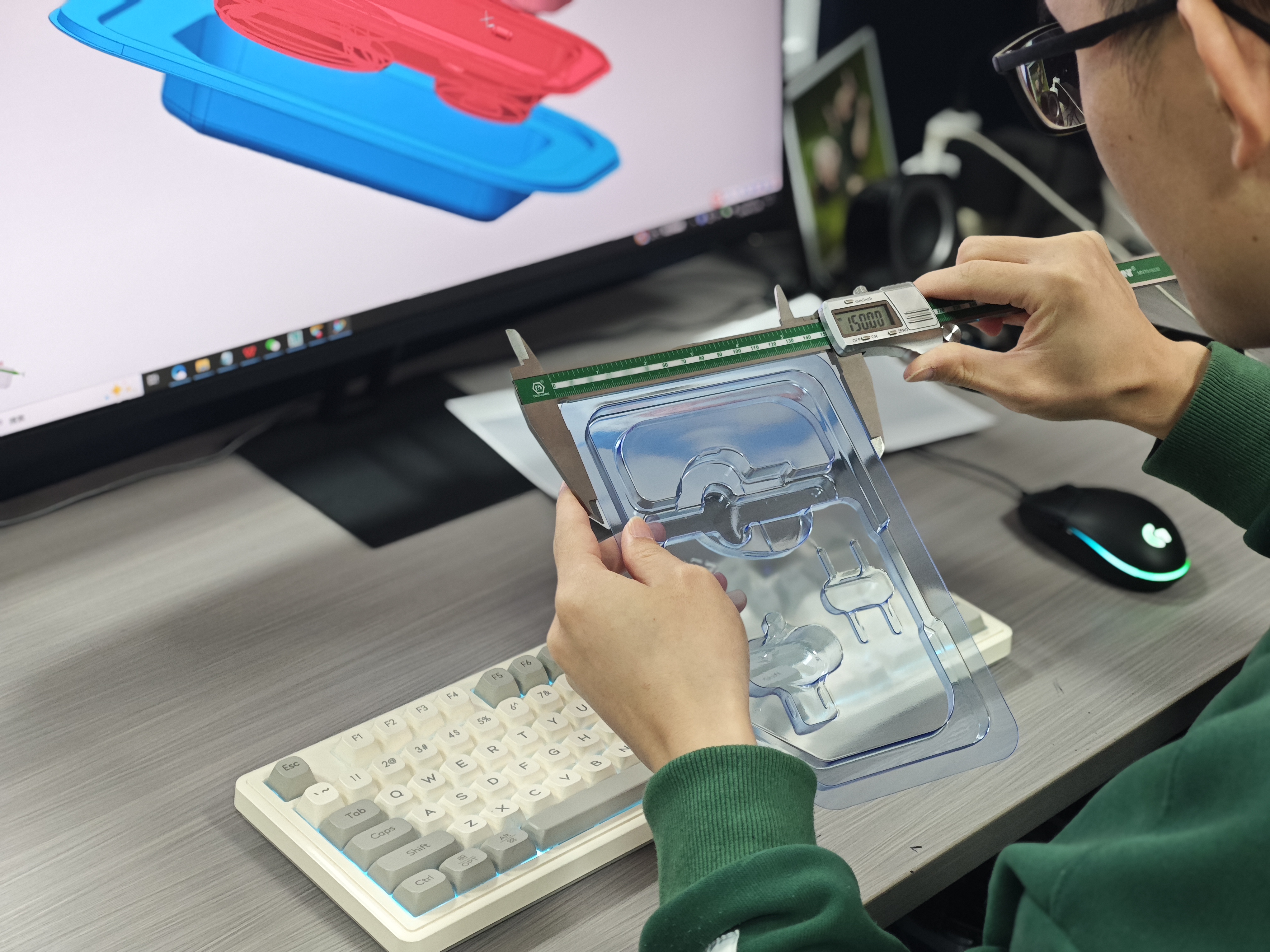

In the blister packaging industry, design is a critical factor that directly impacts product quality and performance. Adhering to established design standards ensures that blister products meet functional and durability expectations during both production and end use. Below are key design requirements that engineers and designers should follow:

The choice of blister material must align with the product’s intended application. Different materials offer varying properties, such as heat resistance, cold resistance, chemical resistance, and flexibility. Designers must evaluate these characteristics to ensure optimal performance under expected conditions.

Maintaining consistent wall thickness is essential to prevent defects such as warping, weak spots, or uneven shrinkage. Variations in thickness can lead to structural weaknesses, so designers must carefully balance thickness across all sections of the product.

Sharp edges and corners can cause stress concentration and increase the risk of cracking during demolding or handling. Incorporating rounded edges enhances durability, improves aesthetics, and facilitates smoother production.

Sudden changes in wall thickness can create stress points, leading to premature failure. Designers should implement smooth transitions between thick and thin sections to distribute stress evenly and enhance structural integrity.

For blister products subjected to mechanical loads or pressure, reinforcing features such as ribs, gussets, or thickened support areas should be integrated. These enhancements improve load-bearing capacity and prevent deformation or breakage during use.

An efficient mold design is crucial for high-quality blister production. Proper mold engineering ensures consistent forming, minimizes material waste, and optimizes cycle times, ultimately reducing manufacturing costs.

Successful blister design requires a holistic approach, considering material properties, structural stability, manufacturability, and mold efficiency. By adhering to these standards, manufacturers can produce high-performance blister products that meet industry demands, enhance customer satisfaction, and strengthen competitive advantage.

info@yinsopack.com

+86 15014837000(Wechat/WhatsApp/Skype)

NO.59 Meilin Road, Dalingshan Town, Dongguan City,Guangdong Province, China

Get a Free Prototype + Compliance Report Within 5 Days

Yinso Packing has been a leading figure in the medical packaging industry since 2007. We are committed to providing reliable, cost - effective, and innovative rigid thermoformed packaging solutions to top medical companies.

© 2025 Dongguan Yinso Medical Packaging Co.,Ltd All Rights Reserved.

AddressNO.59 Meilin Road, Dalingshan Town, Dongguan City,Guangdong Province, China

Emailinfo@yinsopack.com

Tel(Wechat/WhatsApp/Skype)+86 15014837000

About Us Medical Blister Packs Products Capabilities Blogs Contact Us